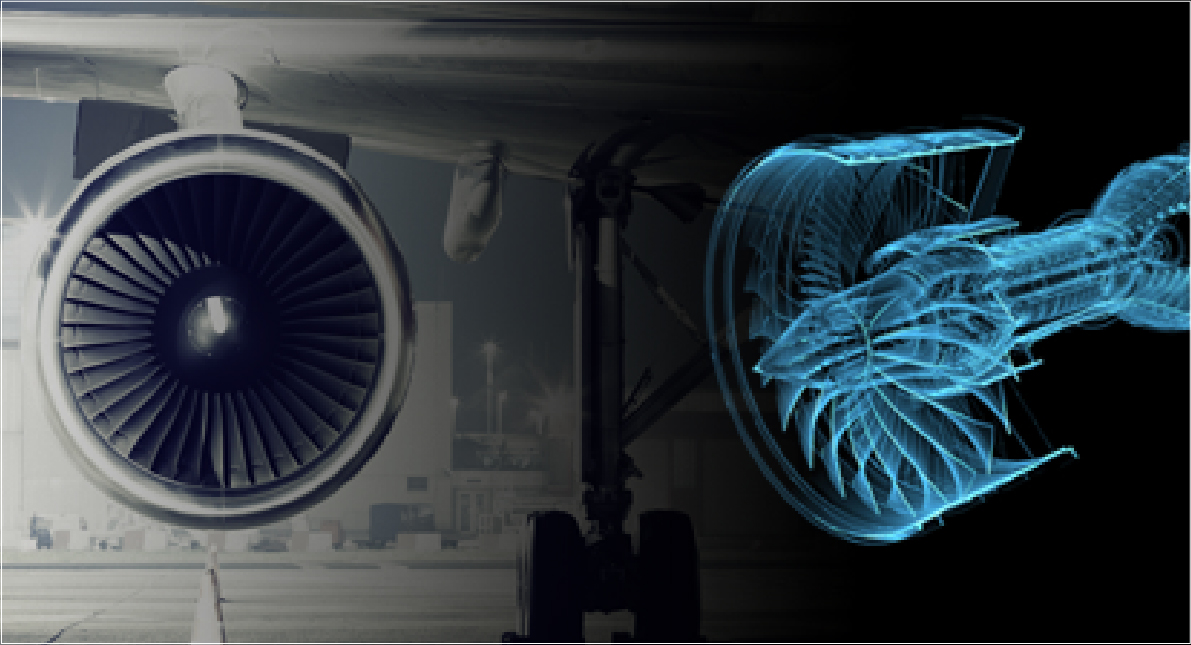

Our Digital Twin solutions create a new business asset: “Knowledge as a Service”, as an enabling factor to set up a 4.0 Smart Factory as well as the digital and virtual reproduction of all real systems.

Digital Twin is an advanced decision support system based on advanced simulation models that receive real-time data from every company asset. It is a digital environment that enables what-if analyzes and optimizations to improve the efficiency of each asset as well as of the system as a whole.

Maintenance (predictive, planned, ordinary), operators’ and company assets safety as well as training are combined in a single digital world where decisions are taken based on analytical and predictive methods (artificial intelligence) and on a Knowledge Base of data continuously updated (Big Data).

Functionalities

Creation of repositories for maintenance, safety and production procedures with audio files, video, images, texts coming directly from production departments (by using the smart operator functions) or from other archives

Creation of customized items for the implementation of augmented reality functions, even with 3d virtual models

Wizard for the creation of mobile apps with multiple functionalities: augmented reality, sophos-ms personal assistant, access to maintenance and safety procedures, access to machine data, access to photos / video / virtual models, video registration, etc.

Possibility of integration with the company information system in order to provide information for production control according to the latest concepts of industry 4.0

Predictive maintenance based on Artificial Intelligence methodologies

Mobile application for troubleshooting on delocalized plants and machines as well as for operators’ training

Automatic management of multiple languages

Simulation…

Build the digital equivalent of all your assets, carry out simulations with real data to ponder your choices, invest wisely the available resources, increase productivity, reduce costs, diagnose problems, identify optimal solutions, prepare for change , train your team.

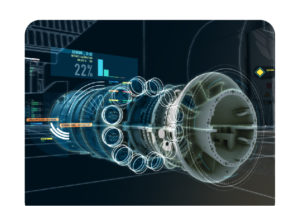

… in an Interactive Virtual world …

Digital and Virtual assets to support production and process design processes, to increase the operators’ potentials both in design and asset management, to improve their learning curves, to enhance training activities, to boost knowledge management and reuse

… Augmented and Smart

Digital and Augmented for fast, visual and objective access to information, for better management of predictive and programmed maintenance processes, for enhanced training processes and troubleshooting of all assets (onsite and offsite) and for higher safety of people and company assets.

Legal and administrative residence:

Via Spagna 240,

87036 Rende (CS) – Italy

C.F./P.IVA 03133320782

Registro delle imprese di Cosenza

N REA CS – 213383

copyright © CAL-TEK Srl

Operational headquarters:

Via P. Bucci 45C,

87036 Rende (CS) – Italy

T: +39 0984 494891

F: +39 0984 494891

E-mail: info@cal-tek.eu

Operational headquarters:

Via Leuca 174

73100 Lecce – Italy

T: +39 0832 349659

F: +39 0984 494891

E-mail: info@cal-tek.eu